A simple, powerful method for finding weak points in your electronics

Electrostatic discharge (ESD) is one of the most destructive and unpredictable threats in electronic systems. Even a tiny spark can corrupt data, reset a microcontroller, or permanently damage sensitive components. Professional ESD guns cost hundreds to thousands of dollars — but there is a surprisingly effective alternative hidden inside an everyday object:

The piezo igniter from a disposable lighter.

This tiny device generates a high-voltage pulse capable of reproducing many ESD-induced failures, making it an excellent low-cost tool for electronics debugging and robustness testing.

How the Piezo Igniter Works

A piezo igniter uses a spring-loaded hammer that strikes a piezoelectric crystal. When compressed suddenly, the crystal generates a very high voltage:

- Up to 15–25 kV peak

- Pulse width in the nanosecond range

- Very high dV/dt

- Extremely low energy (safe to touch, but dangerous to electronics)

This makes it an almost perfect amateur ESD generator.

Why it’s useful for debugging

Electronics that are poorly protected against ESD may show:

- Glitches

- Microcontroller resets

- USB disconnects

- Communication failure (UART, SPI, I²C)

- OLED / LCD corruption

- RF module dropout

- Complete device lockups

The piezo element allows you to reproduce these issues instantly and repeatedly during development.

How to Turn a Piezo Igniter into an ESD Tool

You can salvage a piezo igniter from:

- A cigarette lighter

- A grill igniter

- A click-style gas stove lighter

- A cheap igniter module from a hardware store

Once removed, you have two typical output styles:

- A single high-voltage electrode

- Two electrodes (HV and return)

For debugging electronics, you typically need only the single-tip output. The return path will flow through your body to ground, making the discharge not identical to an IEC-standard ESD pulse, but a real human-body ESD event. This actually helps expose real-world ESD weaknesses in a design.

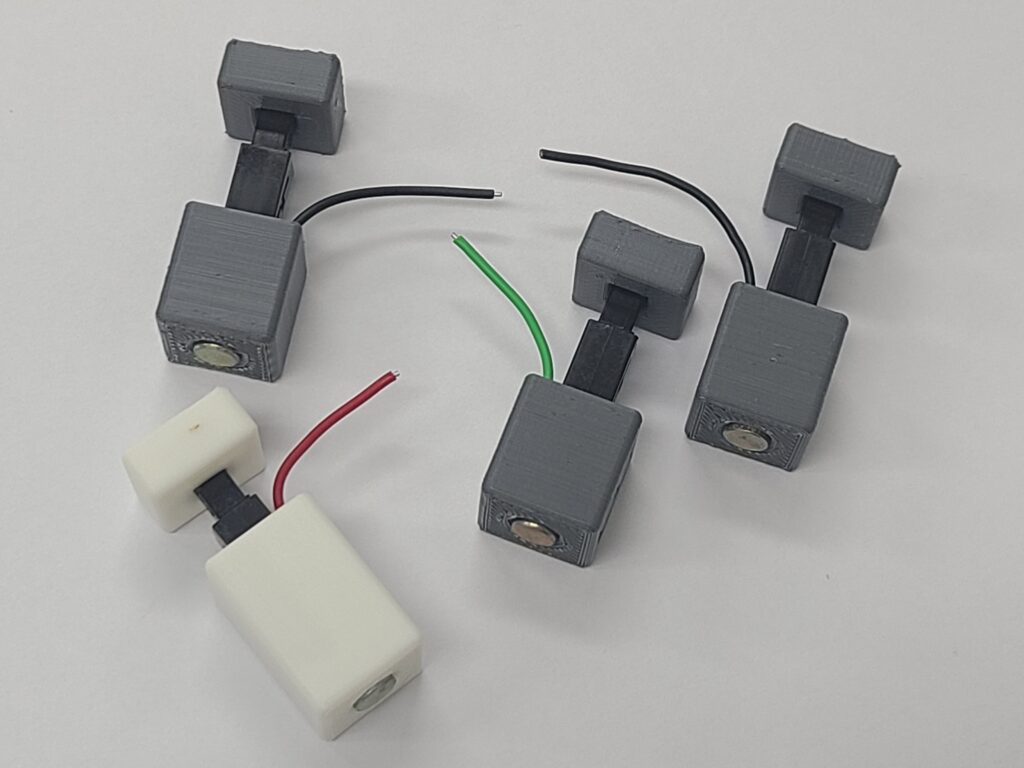

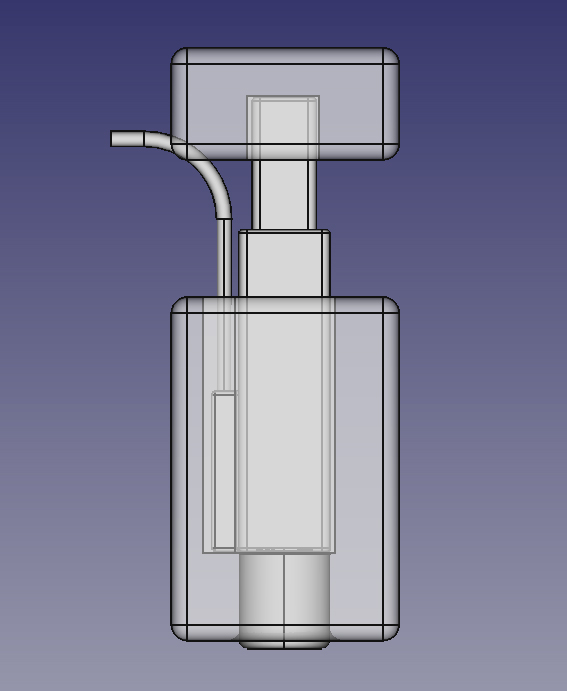

I designed simple two pieces 3D model ready to be printed on a 3D printer. Piezo elements have small dimennsional tolerances, as well as 3D printers have some tolerances. I designed Small, Normal and Big models marked as S, N and B where you can mount the igniter in.

Custom 3D-Printed ESD Tool Enclosures

I designed a set of simple two-piece 3D-printable housings.

Because piezo igniters come with small manufacturing tolerances — and 3D printers also have size variation — I created three enclosure sizes:

- S — Small

- N — Normal

- B — Big

In most cases, the Normal housing will fit perfectly. If you encounter any tolerance issues with your specific piezo igniter or 3D printer, try the Big or Small variant accordingly.

How to Use It for ESD Testing

Important:

This device can easily destroy sensitive circuits if misused.

Use on prototypes, not production hardware, unless you understand the risks.

As with a professional ESD gun, that tiny tool can be used in conact discharge and air discharge. If your hardware designed with ESD tolearnce, ESD shots in to ground or frameground must not lead to hardware damage. Depennding on specific equipment sertification requirements, the fimware must have no unrecoverable states.

-

Test enclosure seams and gaps

Discharge near:

- enclosure joints

- USB openings

- button gaps

- cable connectors

Observe whether the system resets or glitches. If you see corruption, add ESD clamps, series resistors, common mode chokes or TVS diodes.

-

Check ground reference stability

A quick discharge across enclosure screws or shielding points often reveals:

- missing ground stitching

- high-impedance chassis connections

- noisy analog ground

Why It Works Surprisingly Well

A lighter piezo pulse resembles real-world ESD:

| Property | Typical Human ESD | Piezo Igniter ESD |

| Voltage | 2–30 kV | 10–25 kV |

| Pulse shape | Very fast, high-frequency | Very fast, high-frequency |

| Energy | Low | Very low |

| Current | Short but intense | Similar scale |

| Interference | Radiated + conducted | Radiated + conducted |

This makes it an excellent poor man’s ESD gun.

Of course, it is not calibrated, nor standardized — but for finding design weaknesses, it is highly effective.

What This Method Cannot Do

A piezo igniter is NOT a replacement for:

- IEC 61000-4-2 certified testing

- Surge or EFT testing

- Contact discharge assessments

- Repeatable laboratory measurements

However, it is perfect for design-stage robustness testing.

A few cents of protection can save a device from field failure.

Conclusion

A piezo igniter from a lighter is an incredibly practical, low-cost ESD debugging tool. While it cannot replace certified laboratory testing, it excels at highlighting fragile parts of your circuit early in development.

It allows engineers and hobbyists to:

- Expose hidden ESD vulnerabilities

- Improve circuit robustness

- Test grounding and shielding

- Validate protective components

- Debug communication failures

For the cost of a disposable lighter, you gain a surprisingly powerful diagnostic tool.